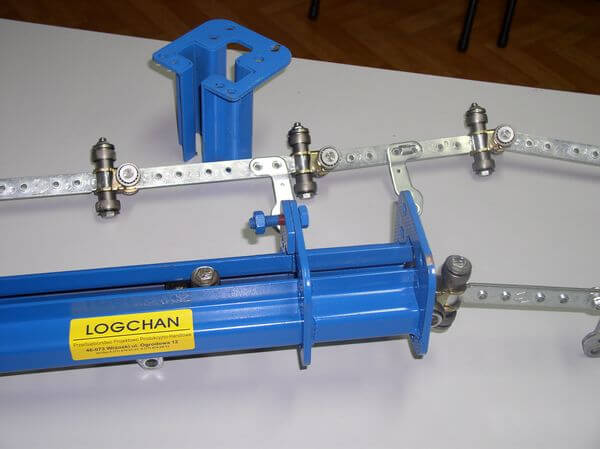

We provide professional support in selection of the most suitable industrial gas burners, so that they perform in the best possible way in production processes. In case of older burner systems, we advise you when choosing replacements available on the market.

Find out more at www.palnikiprzemyslowe.com.pl